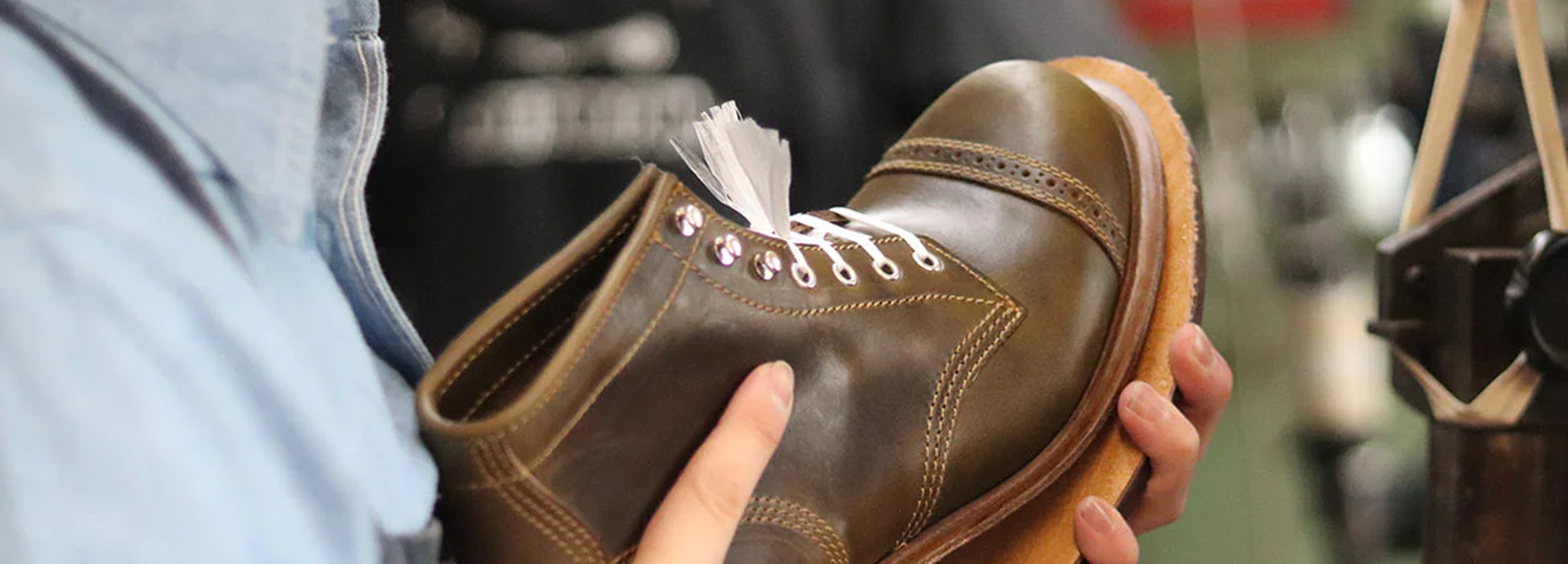

Outsole, Stitching, Heel & Edging

Every visible element matters. We attach top-grade outsoles from Japan and the USA, tailored to each design. The outsole stitching is entrusted to a single master craftsman for a clean and beautiful finish. Heels are secured with nails and heated adhesive, while edges are shaped in three phases by hand for balance and style.

#3-1

Outsole

The outsole is where the boot meets the ground - its role is both practical and defining. After the sole is carefully cut to size by machine, it is joined to the upper with precision and care. We choose only the highest quality outsoles to ensure durability, comfort, and performance in the real world. Whether it’s rugged traction or refined wearability, every outsole we use is selected to complement the purpose of the boot or shoe. Our outsoles are proudly sourced from trusted manufacturers in the USA, Japan, and Italy, where quality and heritage craftsmanship remain uncompromised.

#3-2

Outsole Stitching

Outsole stitching is where craftsmanship and function come together. In Goodyear welted construction, the outsole is stitched to the leather welt—a strip that runs around the perimeter of the boot, joining the upper and insole. This visible stitching isn’t just decorative; it’s a sign of durability, securing the sole while giving the boot its finished look. Executing clean, consistent stitches by machine requires steady hands and years of experience, and very few master this step. At John Lofgren Bootmaker, this process is entrusted to only the most highly skilled craftspeople. Goodyear welt stitching also makes resoling straightforward: the welt protects the upper, allowing the outsole to be replaced over the life of the boot.

#3-3

Heels

The heels play a critical role in both stability and durability. At John Lofgren Bootmaker, we secure the heel to the outsole using a time-tested combination of nails and heat-activated adhesive. This dual approach creates a strong, lasting bond that holds firm through years of wear, even in harsh conditions. Every heel is carefully aligned and set by hand, ensuring not only strength but balance and comfort with every step. It’s one more example of how we build our footwear to endure, not just for today, but for the long haul.

#3-4

Edge Grinding / Coloring

Shaping the edges of the sole is a skill that relies entirely on the hands and instincts of the craftsman. Using a high-speed rotating blade, the edges are ground in three carefully controlled stages—moving from rough to fine—to achieve the right balance of form and function. There’s no template or guide; every pair is shaped by the craftsman’s eye and experience to achieve the designer's vision. The final shape reflects the subtle artistry and steady hand behind every John Lofgren Bootmaker product. After the edges have been carefully ground and smoothed, they are hand-finished with color to match or thoughtfully complement the upper. This process serves both an aesthetic and protective function, helping to seal the leather fibers and guard against moisture. Our craftspeople meticulously apply each coat of edge dye, layer by layer, followed by gentle polishing to achieve a rich, even finish. Whether subtly blending with the upper or creating a striking contrast, this step exemplifies our commitment to refined craftsmanship and long-lasting beauty.