Polish, Inspection, and the Final Touch

After polishing, inserting insoles, and lacing, each pair undergoes a final inspection. Only then is it deemed ready — packed and shipped to customers and retailers around the globe, prepared to walk through life with you.

#4-1

Finishing

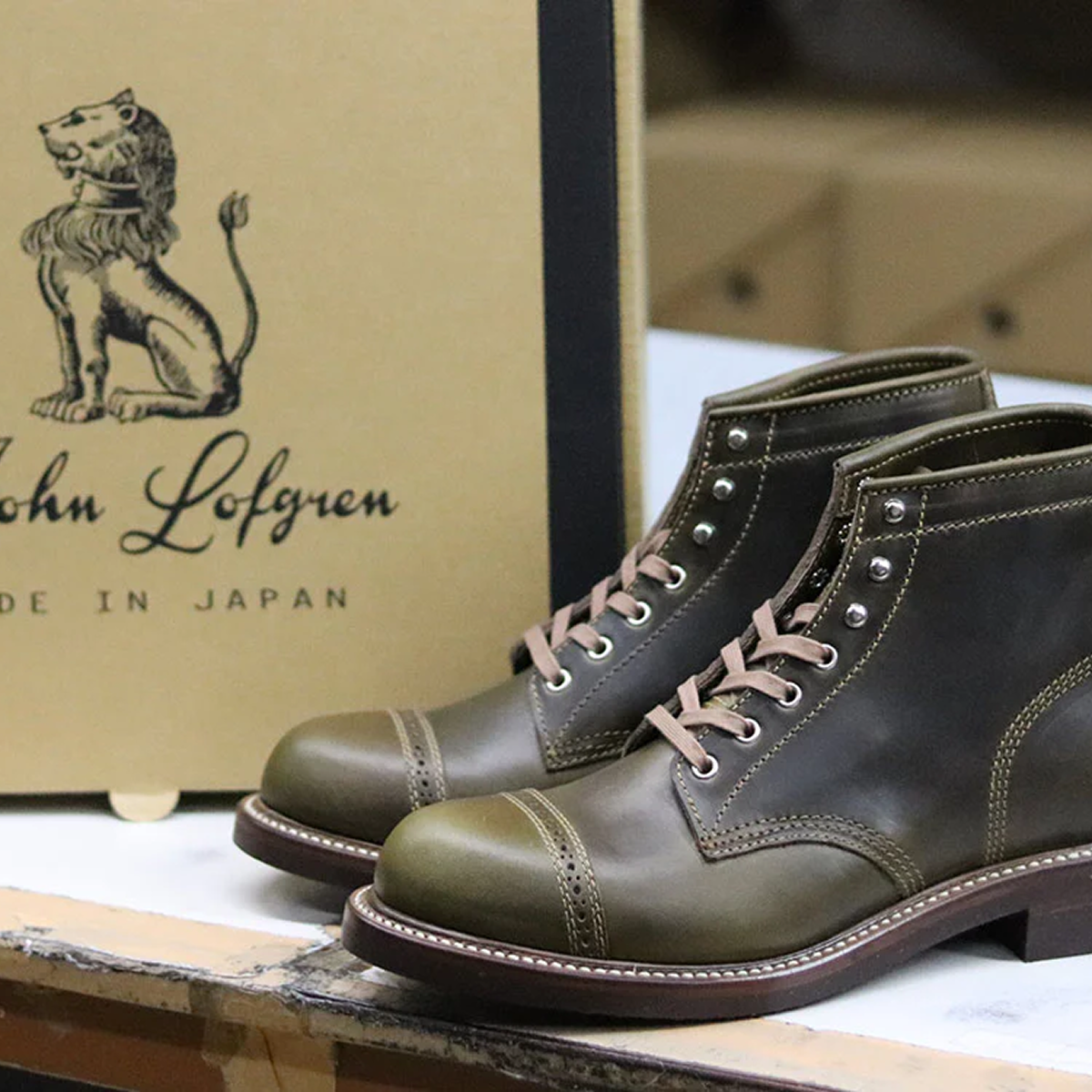

The finishing process is where everything comes together. Each pair is carefully cleaned to remove any oils or debris from construction, then hand-finished with cream and polish to nourish the leather. Insoles are in place, laces are laced, and the boots or shoes are ready to be worn. Finally, every pair undergoes a detailed inspection to ensure it meets our exacting standards. Once approved, they’re placed in protective bags, boxed by hand, and often accompanied by a John Lofgren Bootmaker catalog.

#4-2

Completion

With final inspection and boxing complete, each pair of boots or shoes leaves the factory and heads to our distribution office in Sendai. There, they are carefully prepared for worldwide delivery to our retailers and customers. This marks the beginning of the next chapter, as they leave our hands and are ready to accompany you wherever your journey leads.

Please note that these descriptions highlight only a small part of the many steps and skilled hands involved in the making of John Lofgren Bootmaker boots and shoes.